Custom Pigments

With over 24,000 concrete colors, we match all Pantone, Benjamin Moore and Sherwin Williams colors everyday. We can also match virtually all Epoxy Terrazzo colors in Cement Terrazzo. Hundreds of Custom Pool Colors including Black Pools that stay Black without using any Carbon Black.

Customers from all over North America and beyond trust Clarke to match any color in concrete and cement systems.

Pigment Dispersion Techniques

Concrete is composed of two main ingredients, cement paste and sand/aggregate (S/A). The properties of the cement paste are affected by the presence of the S/A, specifically during the short period of time when blending in the mixer. When water is added, cement particles are dispersed and begin the chemical conversion. However, the cement particles are in fact suspended in water, even in low and zero slump concrete, and cannot pack together as efficiently when they are in the presence of the much larger S/A. This particle packing is commonly known as the wall effect. During mixing, which can be from two to six plus minutes, the shearing effect of the S/A can cause the water to separate from the cement particles. The result is a very narrow region around each S/A with fewer cement particles and thus more water. This is called the interfacial transition zone or the ITZ.

The ITZ is a region around each S/A with a higher water to cement content ratio and therefore, higher porosity than the bulk paste. The ITZ varies in thickness from point to point around each S/A. Because of the larger pores, the ITZ is characterized by a higher presence of larger crystals, calcium hydroxide. The ITZ has important effects on the properties of the concrete, especially long term surface durability performance and color fading.

Unweathered vs. Weathered 60 Months

Evidence of faded colored concrete is found all over the world.

The original color is just not as vibrant after a few years in the field. Paste removal exposing sand and aggregates is the common cause (see above). The pigment/paste layer is eroded and removed over time with the underlying sand and aggregates exposed. The result is a lower intensity, lighter, different shade of concrete than the original. The pigment, which is almost always Iron Oxide, has not changed chemically but has simply been removed at the ITZ region. When other performance pigments like Blue and Green are used, the contrast in color between pigment and S/A is even greater. This is why complete dispersion is critical when making concrete.

Unweathered vs. Weathered

With pigment particles added into the ITZ equation, things get more complicated. Pigment is a combination of three forms – primary particles, loosely bound agglomerates of primary particles and hard fused aggregates of primary particles. Granular and liquid colors contain differing ratios of these three forms but in general, once the pigment hits the mixer and begins dispersing, the following occurs. As the cement chemical conversion begins in the first 60 seconds in the mixer, the primary pigment particles wet. There is no bond at this point because chemically the cement is just beginning it’s reaction and conversion.

The surface area of the loosely bounded agglomerates of pigment particles is a different story. Think of this as pyramid stacks of micro ping pong balls with a space in between each one. The single ping pong ball is the primary particle and the stack is the agglomerate. The developing ITZ area is not going to be the same around each pigment stack.

When using color for exterior product, the objective of any cement and concrete producer is to keep the pigment particles attached to the binder. The cement is the binder or the glue keeping everything attached to each other. The ITZ plays a very important role in how the pigment is kept attached within the binder. If excess water is present when concrete is made, the ITZ is more pronounced and a weaker link is formed. The amount of water added should only be enough to chemically convert 100% of the cement. With limited mix times and production rates required by most producers, this is not an easy task. Water should never be thought of as the lubricant to make concrete flow or pack. Excess water is why concrete cracks, degrades and falls apart over time.

Water is both a necessity and enemy of the cement concrete system, especially in colored concrete. The higher the water content, the lighter the color and the weaker the cement paste.

Why does more water create a lighter color? Try this: pour a soda or a cold beer into a glass and watch what happens. The foam, which is the same fluid, is much lighter in color. The small air bubbles in the foam are scattering the incoming light, therefore the lighter color. This same phenomenon happens with excess batch water in concrete. Tiny air bubbles are created, scattering the light and giving the appearance of a lighter color. The objective should always be to use as little water as possible when making any concrete.

Pigment Loadings

Cement is a binder that must be covered with pigment particles to shift the cement color in various directions. It is that simple. The more we cover up the cement binder surface color with pigment particles, whether grey or white cement, the more saturated the color becomes.

Look at the color of the pigment powder itself. In general, this shows what a maximum loading will look like. Some pigments can be added at loadings up to 10% to reach this saturation stage. Other pigments achieve full saturation at about 2.0%.

The key parameter is the desired final target color – this determines which combination of pigments are required.

The following tips will save you time and effort when working with pigments. The difference in color between a 1% loading and a 2% loading is greater than the difference between a 5% loading and a 6% loading. Why? Because you are adding 100% more pigment particles between a 1% and 2% loading and only adding 20% more pigment particles between a 5% and 6% loading. The color difference is minor when comparing a 5% and 6% loading, however the 1% and 2% will appear very different.

Black BK555 is a game changer to hit very dark concrete colors. Black Iron Oxide 451 at an 8.0% loading is a nice deep gray color but color cannot shift in various directions like a true Chocolate color because it is saturated leaving little room to add other pigments. BK555 at 3.0% is a far darker gray than any Black Iron Oxide at 8.0%. Add 1.0 % BRICK to BK555 at 3.0% and watch out – Deep Chocolate Browns as dark as a Chocolate Bar are a reality. Dark accent colors like Black, Navy Blue, Emerald Greens, Deep Burgundies and any Clay shades are just a few to compliment lighter field colors, creating a completely NEW concrete color palette.

The color combinations are truly endless.

Specialty Concrete AdMixtures

Very small amounts of water are needed to chemically convert and react cement particles, usually a W/C ratio of 0.32 or less. Excess water required for placing or compacting concrete is the enemy of high performance concrete and the resulting concrete strength is always weaker. And this excess water washes out and lightens all pigments and creates efflorescence. Performance chemicals or admixtures play a key role in reducing the excess water amounts and improve concrete strength AND produce richer and more vibrant colors.

Water is required to chemically convert cement powder into a complex crystal lattice multi silicate structure. BUT only enough water should be added to accomplish this chemical reaction. Water is H20 and both H and O are required to chemically convert cement into the silicate structure. Adding more water to create flow or to improve compaction is very common, however it is the absolute worst thing to do from a chemical point of view.

Admixtures are added for a variety of reasons. From the lower price per gallon flavor of the day to super low dosage rates. From a color and pigment perspective, rarely are admixtures used as a chemical to help the chemical bond of the pigment particle within the ITZ zone. While low and very low admixture dosage rates will help control efflorescence and absorption rates, our objective is more focused at the S/A & ITZ zone interface and the attachment and bond of the pigment particles to the silicate structure. When excess water is present, the % of excess water does not get converted in the main chemical reactions taking place. Efflorescence, haze, washed out colors, shrinkage and cracking are all evidence of excess water. Furthermore, the concrete surface is the first to dewater from evaporation so the required water is no longer available to chemically react to the denser silicate phases. This results in a higher calcium hydroxide % which is weaker than the other denser phase silicates.

An admixture designed for colored concrete should accomplish two goals. The first is to reduce the excess water required for flow and to fill molds. The second is to KEEP the water that has been added inside the body of the concrete to allow it to completely react and convert to the multi silicate structures.

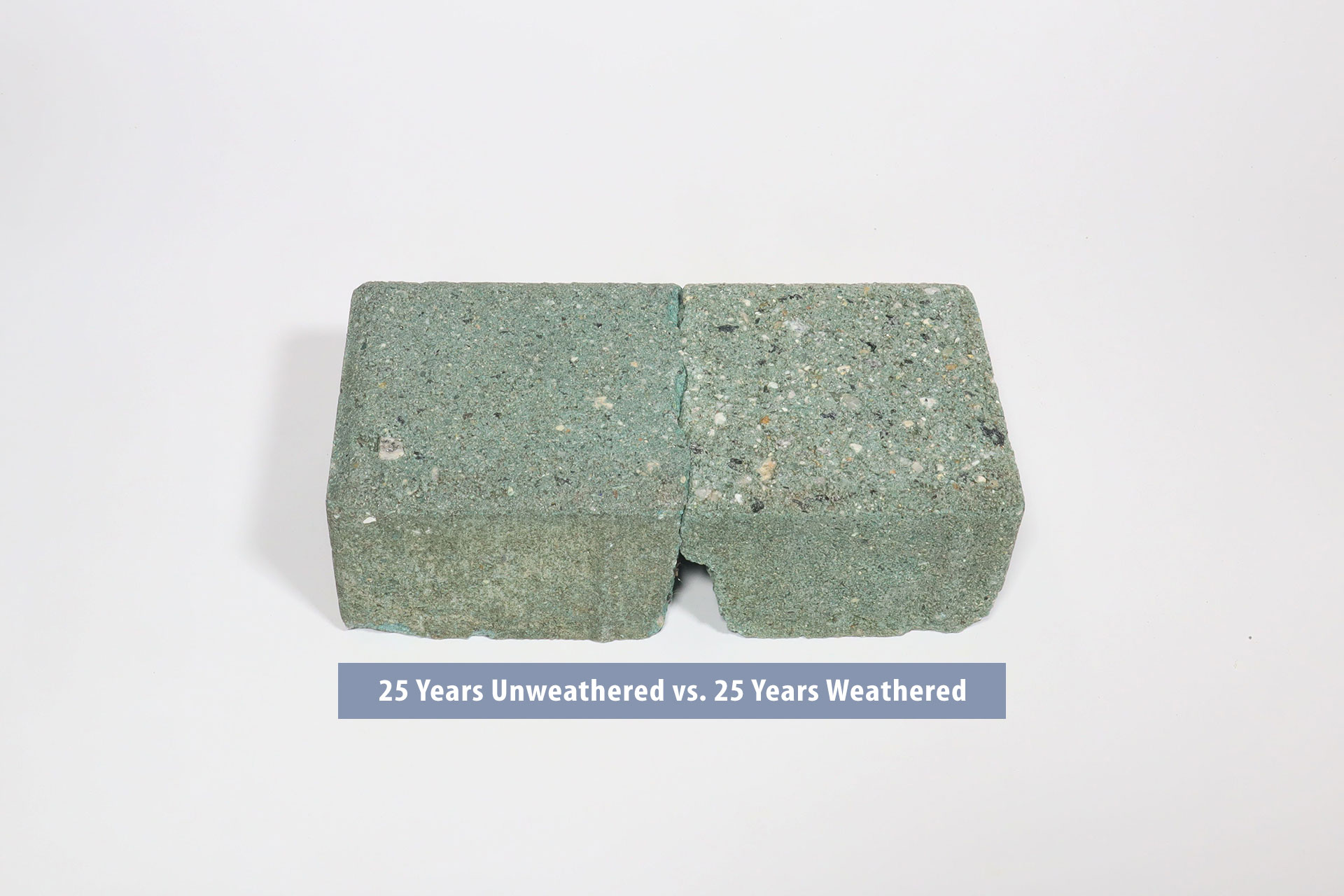

Weathered 25 Years vs. Unweathered

This green paver was produced in 1998 at a 1.0% loading using a unique Copper based Green pigment, extremely durable just liek Chromium Green Oxide. During manufacturing on the wet side, water could be beaded on the paver surface for several minutes. One half has been weathered for 25 years in Atlanta GA, an extremely difficult weathering test for concrete. The other half is the reference unweathered portion and original color. While some color loss has taken place, it is still green and well within acceptable tolerances and demonstrates how concrete color longevity can be achieved when pigments are used properly.

A high performance admixture condition ideally should be used to help the performance of all pigments when coloring concrete but sadly this is not always the case. Many of our customers see the results with stronger concrete, darker colors and the ability to reduce the amount of pigment to achieve a target color. Lower Portland cement consumption and lower batch water consumption will also be important benefits. Clarke MegaMAx TZ and several other specific admixture brands can accomplish these goals. Use less water to make better colored concrete and cement products.